Steam Monitoring Systems

High Accuracy, Low Velocity Flow Rates w/ No Straight Pipe Run Requirements!

Featured Product:

VERIS, Inc. (Armstrong Int'L) 'Accelabar' Flow MetEr

The Application...

A rendering plant in Los Angeles, needed a system that would monitor the steam usage during processing to help optimize boiler efficiency. They use three boilers with two delivery process lines coming into the plant, with multiple distribution lines that stem off of the two main lines.

The Problem...

This facility's main issue is that their process lines have minimal straight pipe runs which are necessary to accommodate 'traditional' steam flow measuring devices, such as Differential Pressure, Vortex Shedding and Ultrasonic technologies.

The Solution...

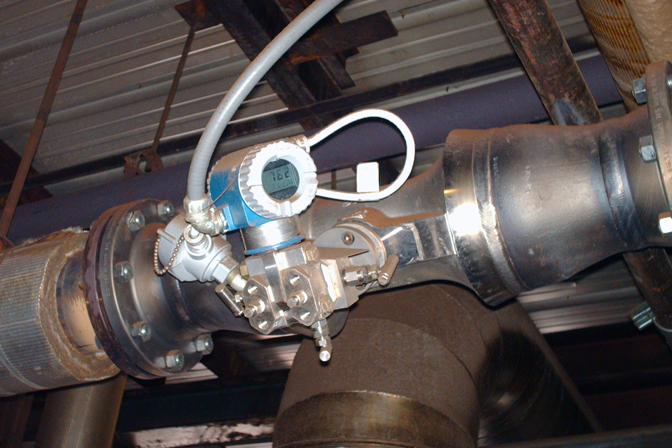

Accurate Measurement Systems, Inc. introduced the client to the VERIS, Inc 'Accelabar' unit. VERIS, Inc. is a product division of Armstrong International, a company that has been servicing the industry for over a century, worldwide. The VERIS Accelabar requires no upstream or downstream pipe diameters and can achieve accuracies of up to +/- 0.5% of flow rate.

This product utilizes two types of technology: (1) a sonic flow nozzle and (2) differential pressure. The inlet throat of the product is similar to a full form venturi meter, which reduces down to a nozzle-like shape that houses a sensing element. AMS, Inc. provided two 8" units with multi-variable transmitters to measure the saturated steam. Included with the Accelabar unit, we provided HART interface modules as well as a Chessell Data Acquisition/Recording System.

The HART interface modules extract the temperature, pressure, density and steam flow via the HART signal (4-20mA DC loop) and delivers this data to the Chessell unit that records and performs specific math functions, such as steam flow rate, totalization and BTU calculations. This is especially helpful for the client to determine each boiler's efficiency by comparing input BTU's to output BTU's. This 'system' is a much more effective way to manage their Preventative Maintenance Program on the boilers while providing more information regarding the steam distribution throughout the plant.

As with any new system, the plant operations team was skeptical about the performance of this system, but they quickly found that not only is the Accelabar unit effective, it's highly dependable. AMS, Inc. not only provided all of the instruments included in this system, but we also did the system's integration which included instrument calibration, programming, start-up and operational training.

VERIS, INc. Accelabar Flow Meter installed on 8" process line

Screen shot of flow details on chessell data acquisition unit